HVAC Case Study

Heineken

Industrial air conditioning units installed in Heineken bottling in Southern Spain

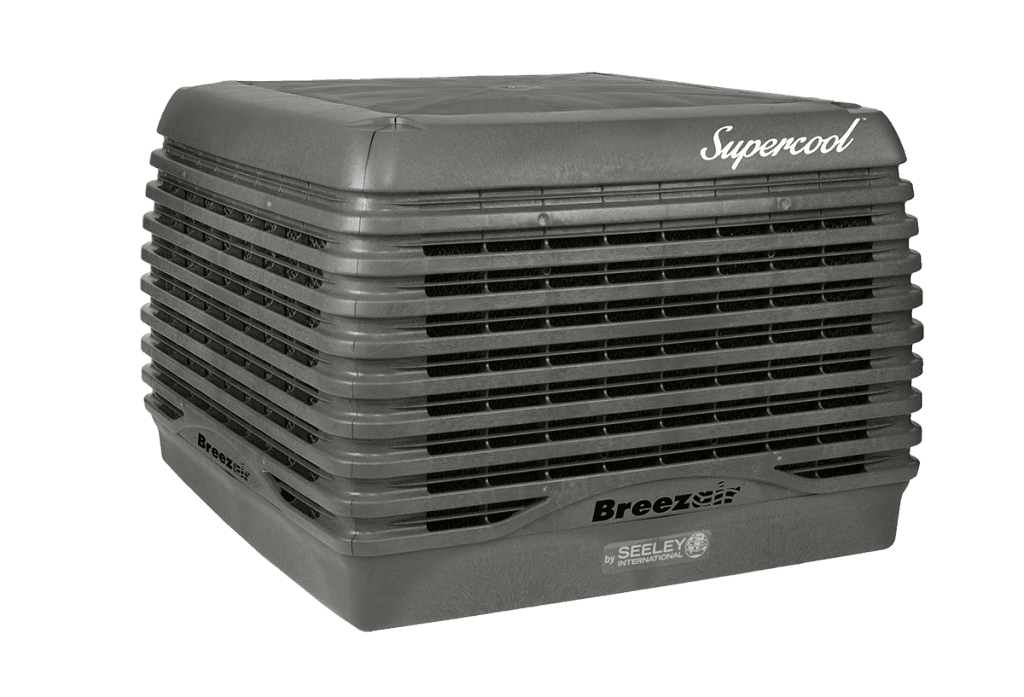

Breezair is the perfect inbdustrial air conditioning unit when it comes to industrial plants such as bottling company

Heineken, fourth largest beer brewing company in the world, has chosen industrial air conditioning units Breezair to cool the production area in Seville (Spain). This way, they have reduced the energy consumption of more than 80%.

Heineken España S.A. chose Breezair adiabatic cooler to cool the production area in Seville. The company has preferred this eco-friendly solution, rather than traditional air conditioning systems. In fact, Breezair can reach the optimal temperature inside warehouses and industry plants, with a reduced electric consumption and without using chemical refrigerants.

Before the installation of Breezair industrial air conditioning units, high temperatures had often compromised the productivity of the Heineken industrial plant, which boasts 25.000 square meters’ area, negatively impacting the health and morale of the workers. Many of them had to leave the production area for a few hours in the hottest parts of the day to refresh, especially because of the heat generated by the equipment involved in the production.

Australair Ecoclimatizaciòn, official Breezair distributor for central and southern regions of Spain, successfully installed 105 Breezair TBA 550, reducing the summer temperatures inside the plant from 38-40°C to a more comfortable 25-26°C. With their optimum efficiency and unsurpassed reliability, Breezair air coolers ensure considerable energy and costs savings to the company, which is extremely satisfied with the new cooling system.

Learn more about Breezair evaporative air conditioning!

HVAC Case Study Overview

Industry

Industrial / Manufacturing

Country

Spain

Region

Andalusia

Technology

Direct Evaporative Cooling

Application

Stand-alone Cooling

Brand

Breezair

Products Used

Breezair Supercool TBA 550 Evaporative Cooler